Necto’s flowing anticlastic surface adapts fluidly, suspended from above, braced against the Arsenale’s columns, or anchored to the ground. Within its undulating geometry emerge three distinct architectural moments: an enveloping cone, a disorienting column, and a hanging mass.

Making of video

Expression

Facts and Figures

95%

biodegradable

100m2

textile surface

12

pieces of knit

40

hours to knit

38.5kg

total weight

10.9PB

DNA material passport

23

programmed LED strips

Features

Light footprint

The majority of materials are lightweight and portable, transported to the Arsenale as luggage via vehicle, commercial passenger flight, and vaporetto without crates or excess waste. The stone footings were sourced from second-choice slabs and delivered by vehicle from nearby Vicenza. At the exhibition’s end, Necto dissolves, leaving no trace—its surface flattened and packed, ready to embark on its next iteration.

Performative and fabrication-aware design

The geometry is form-found accounting for internal stress distribution, fabrication constraints, and material properties, with the aim of enhancing the spatial experience. It is developed through computational structural design and optimisation techniques, and fabricated using CNC knitting machines with natural fibres. Functional grading aligns with principal force flows. The two principle stress directions are materialised as flax fibre inlays in one direction and density variations within the knit architecture in the other. The entire patterning is computationally controlled through fabrication pipelines that automatically generate code for the industrial knitting machines to produce.

Experience design

Luminous threads seamlessly integrated within the textile follow selected stress pathways, forming a constellation of light and spatialized sound. Immersive animations dance across the membrane, transforming the structure temporarily into different environments, only to disappear entirely in the next moment again. The generative light and sound animations embrace lightness, exploring the expressive possibilities of a very minimal visual and sonic palette. Each atmosphere playfully speculates on the tensions between craft and algorithm, nature and technology, emergent process and design intent.

Material Intelligence & Circularity

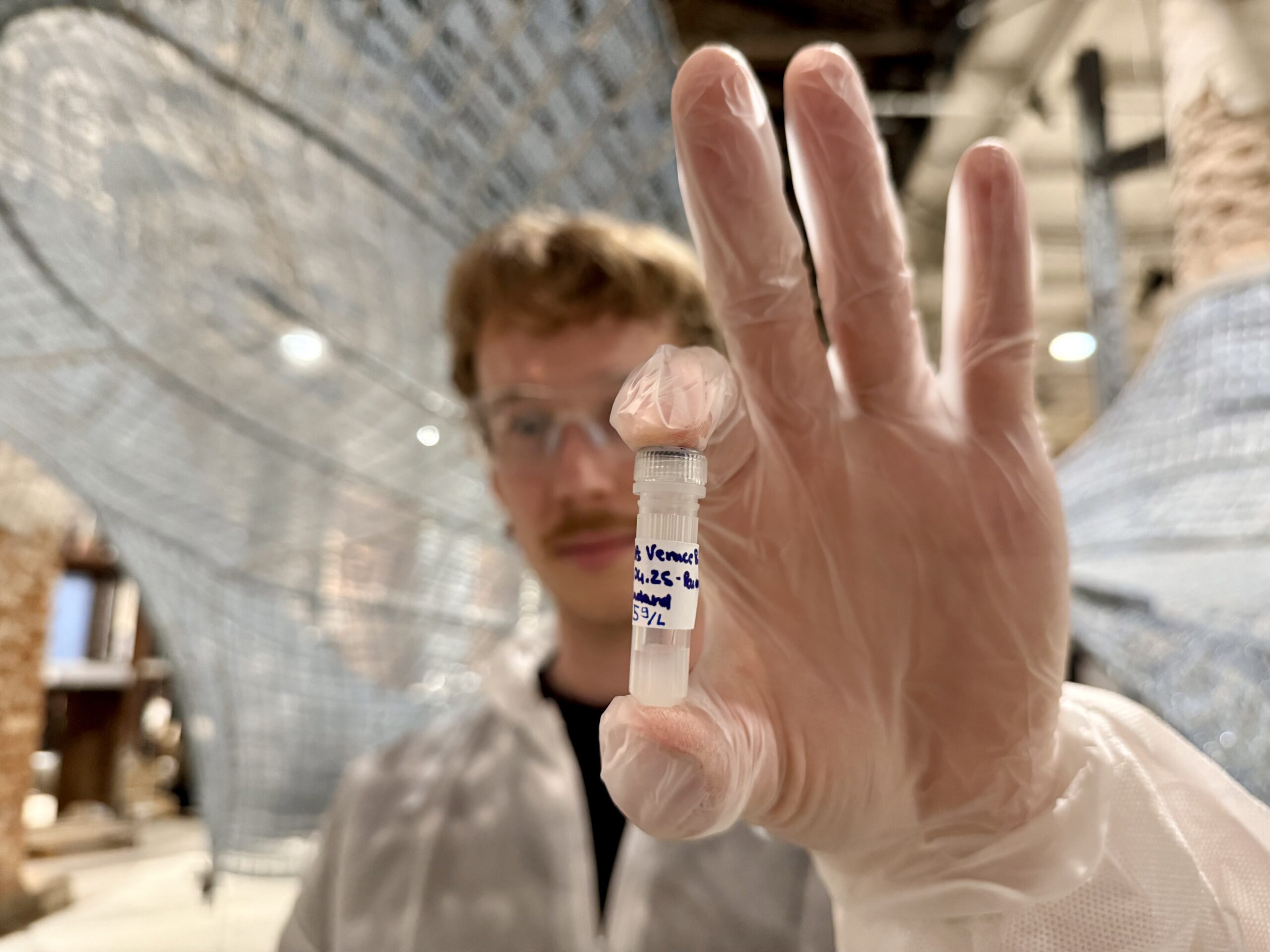

95% of materials such as linen, flax and PVA are locally sourced and biodegradable. The textile’s water-soluble bio-based coating contains digital information encoded on synthetic DNA, borrowing from the expertise of 4 billion years of evolution. The data includes a material passport for all components used and machine instructions to produce the textile. Due to the nature of the DNA, this information will stay intact and part of the structure for its entire lifecycle, ensuring future traceability and accountability. Once the exhibition ends, its coating can be completely dissolved, and the textile can be easily and compactly packed in hand luggage and transported to its next destination.

Furniture – reclaimed aluminium benches

Two Pressure benches and one stool, designed and fabricated by Tim Teven Studio in Eindhoven from 2mm thick aluminium sheets, are positioned at the textile’s lower spans, allowing for moments of contemplation.

Credits

Design

SO – IL: Florian Idenburg, Jing Liu, Marlena Fauer, Demetri Lampris

Tailored Materiality Research (TU Delft/incoming MIT): Mariana Popescu

TheGreenEyl: Richard The

Membrane design and engineering

Tailored Materiality Research (TU Delft/incoming MIT): Mariana Popescu, Valentin Lorenzen da Silva, Niclas Brandt, Nikoletta Christidi

Experience design

TheGreenEyl: Richard The (creative director), Ben Bojko (software lead), Noah Feehan (hardware lead), Saralee Sittigaroon (architectural designer), Arden Schager (creative technologist), Ardak Mukanova (designer)

Structural Engineering

Professorship of Structural Design (TUM): Anass Kariouh, Pierluigi D’Acunto

Membrane fabrication and construction

Tailored Materiality Research (TU Delft/incoming MIT):Mariana Popescu, Nikoletta Christidi

Steiger Participation S.A: Jean-Luc Lepieszko, Jean-Francois Cochez

Bio-coating and DNA data embedding and error correction

Shaping Matter Lab (TU Delft): Kunal Masania, Jasper Groen

Functional Materials Laboratory (ETH): Robert Grass, Francesca Granito

Professorship of Machine Learning (TUM): Reinhard Heckel, Maria Abu Sini

Sound Design

Marian Mentrup

Furniture

Tim Teven Studio

Opening Performance

Riley Watts